3D Compounding

The latest in compounding technology from Randcastle gives you the power of mixing three dimensionally. People ask, “Doesn’t all mixing occur in 3 dimensions? Sure. But almost all single screws mixers act in just one dimension like this: Picture these shapes anchored on the left and stretched to the right. This stretching in one dimension is along the x axis but it can be along any axis or combination. Shear (5) is one is one dimensional mixing. It’s linear with a linear effect. Most mixers are shear mixers (UC and spiral UC or barrier mixing screws i.e. Barr, double wave, Davis, etc..) Linear stretching through elongation (3) may break a strand into droplets. Even so, it’s just a one dimensional stretch like shear.

It’s much better to stretch in two dimensions. The area increase (or the droplet increase) is exponential. Obviously, this stretching is much more powerful than a simple linear stretch. Two dimensional stretching is exponentially more powerful that linear stretching whether into a plane or into droplets. Droplets become exponentially smaller and more numerous. A useful way to visualize the mixing of fine particulate is to imagine that the left (un-stretched) surface densely populated with particles. As the plane is stretched along the two axis, particles move further apart from each other.

Another thing our 3D mixer does is fold a previously stretched plane. The plane could also be broken into droplets and then rolled. The plane could be covered with particulate. When a previously stretched plane is folded, it is better mixed. First two dimensional stretching, moves all the particles further apart from each other and then when you fold them back into each other, they are more evenly distributed.

Pelletizing

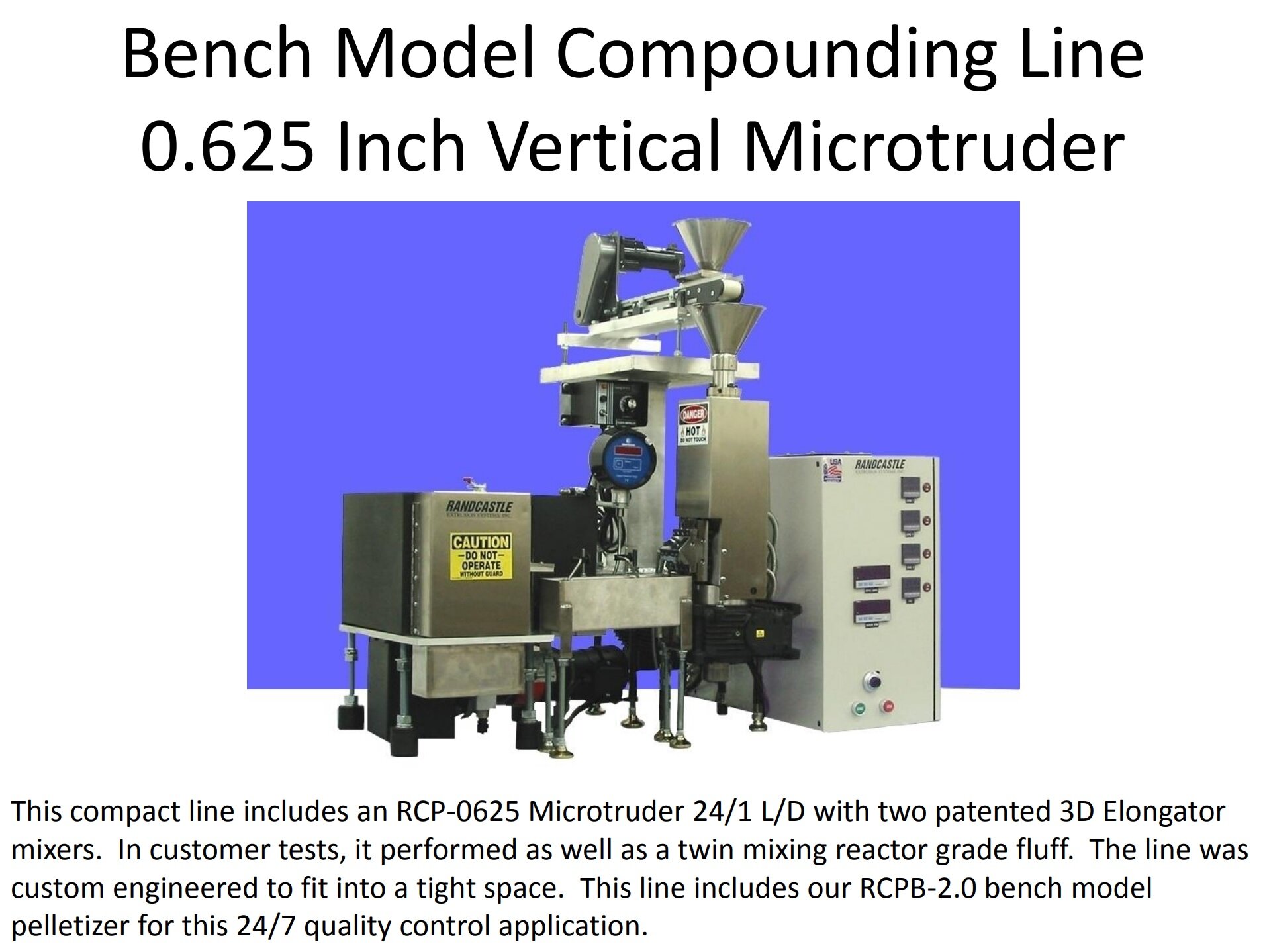

Strand pelletizers pull one or more strands from an extruder through a cooling system (such as a water trough or air cooling conveyor) and slice the strands into pellets. Strand pelletizers are versatile processors of a wide range of materials. Randcastle builds two kinds of strand pelletizers. The first is the traditional rotating knife that shears against a fixed knife. It is made in cutter widths of 1, 2, and 4 inches. Model RCP-1.0 is bench mounted and has a 1 inch wide cutter. It makes pellets between 0.02 and 0.06 inches long. It is designed for light duty lab applications to work with our 1/4 to 5/8 inch extruders. Model RCP-2.0 has a 2 inch wide cutter and model RCP-4.0 has a four inch wide cutter. These pelletizers were designed to solve the problems most often associated with small pelletizers: strand drop out, ineffective pulling, and maintenance headaches. Select from many options to customize these pelletizers to your needs. Randcastle also manufactures a fragile strand pelletizer for strands that are too delicate to pass through the nip roll of a traditional pelletizer. So, this pelletizer is particularly useful for strands that lack strength such as drug filled low molecular weight strands. It can be integrated with an air cooling conveyor rather than a cooling trough.

Cantilevered cutting chamber: The cantilevered design allows easy access to all the parts that may need cleaning and maintenance. A quick release locking collar holds the rotating cutter and the nip rolls. These locking collars are self aligning to simplify installation. The fixed knife is carbide for wear resistance and it is four sided for extended life. The swing guard is made from stainless steel and activates a safety switch when opened to stop the rotating knives